CNC Router: The craft of woodworking, with its rich history and tradition, has been profoundly transformed by technology. Among these technological advancements, the Wood CNC (Computer Numerical Control) router stands out as a game-changer. This sophisticated tool has reshaped the landscape of woodworking, enabling precision, efficiency, and creativity that were unimaginable a few decades ago. This blog post explores the Wood CNC router, its functionality, benefits, and the impact it has had on the woodworking industry.

Understanding Wood CNC Routers

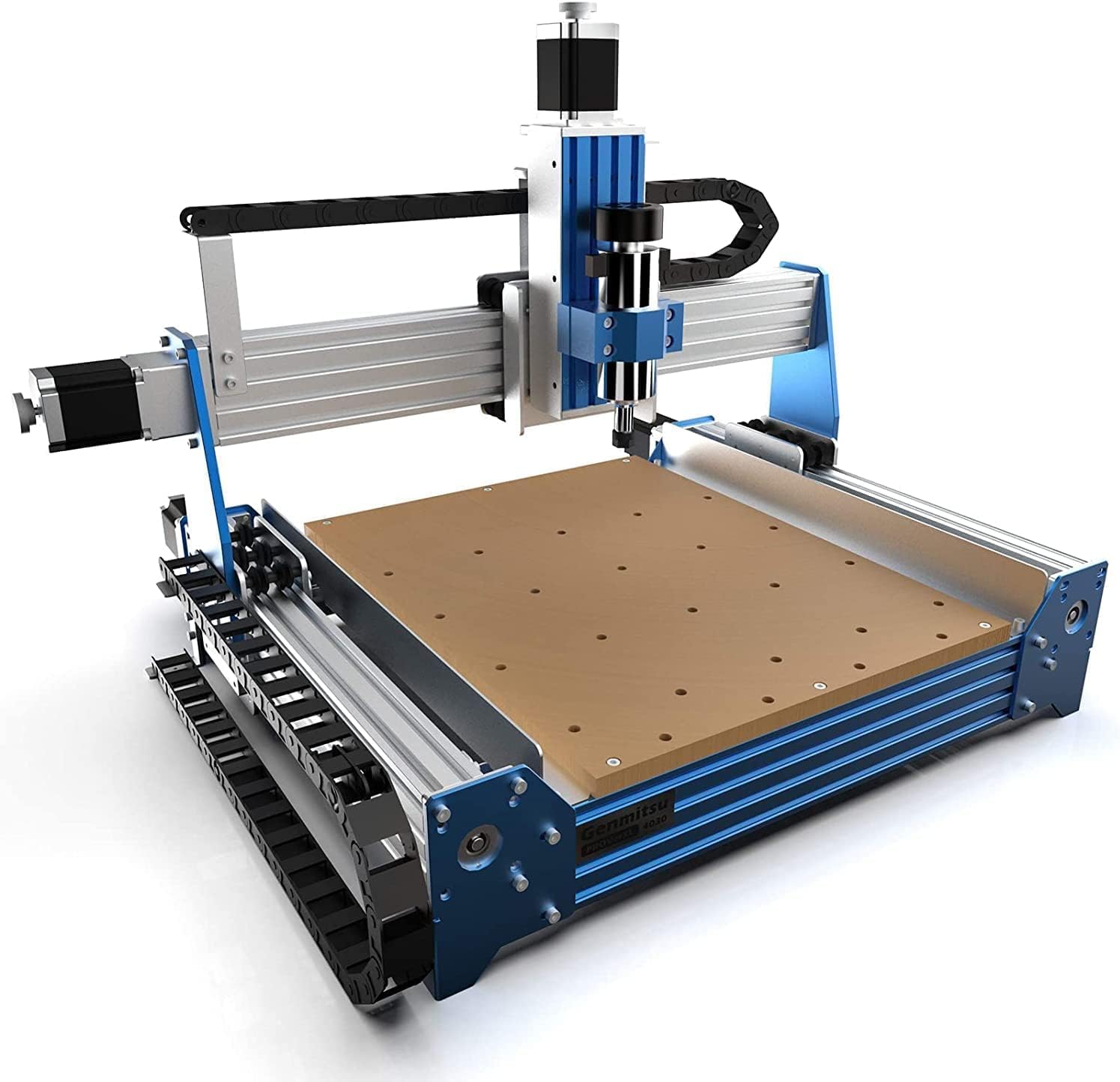

A Wood CNC router is a computer-controlled machine used for cutting, carving, drilling, and engraving wood. It operates on a set of digital instructions derived from a CAD (Computer-Aided Design) file. The router meticulously follows these instructions, allowing for the creation of intricate designs and precise cuts that would be difficult, if not impossible, to achieve manually.

The core components of a CNC router include the controller, cutting tools, and the bed where the wood is placed. Operators input their design into the machine via CAD software, which then translates the design into numerical code. This code controls the movement of the router, ensuring each cut is executed with exact precision.

Benefits of Wood CNC Routers

- Precision and Accuracy: The hallmark of CNC technology is its precision. CNC routers can achieve tolerances within fractions of a millimeter, ensuring every piece is consistent with the last.

- Complex Designs and Customization: With CNC routers, woodworkers can bring the most intricate designs to life. From elaborate patterns to custom lettering, these machines open up new possibilities for personalization and creativity.

- Increased Productivity: Automation means faster production times. What might take hours to complete manually can be done in minutes with a CNC router, allowing for larger volumes of work without sacrificing quality.

- Material Conservation: CNC routers minimize waste through the efficient use of materials. By optimizing cutting paths, they make the most out of each piece of wood, reducing the cost and environmental impact.

- Safety: With the machine doing the cutting, there’s less risk of accidents associated with manual routers. This makes the woodworking environment safer for operators.

Impact on the Woodworking Industry

The introduction of CNC technology has had a profound impact on the woodworking industry. Small businesses and hobbyists alike have gained access to capabilities that were once the exclusive domain of large manufacturers. This democratization of precision woodworking has led to an explosion of creativity and innovation.

Education and training have also evolved to incorporate CNC technology, with many institutions offering courses in CNC operation and design. This education is critical, as mastering CNC technology requires both technical skills and creative thinking.

Choosing the Right CNC Router

Selecting a CNC router involves considering several factors, including size, power, and the specific needs of your projects. Entry-level machines are suitable for hobbyists and small projects, while industrial-grade routers cater to high-volume production and more demanding tasks.

Software compatibility is another crucial consideration. The design software must not only be compatible with the CNC router but also be user-friendly to streamline the design process.

Future Trends

As technology advances, we can expect CNC routers to become even more sophisticated. Improvements in speed, precision, and user interfaces are likely. Additionally, the integration of AI and machine learning could further optimize design and production processes, making CNC woodworking more efficient and creative.

Sustainability is another area of focus. As environmental concerns grow, the woodworking industry is looking for ways to reduce waste and energy consumption. Future CNC routers may be designed with sustainability in mind, using less energy and maximizing material efficiency.

Conclusion

The Wood CNC router has revolutionized woodworking, bringing unprecedented precision, efficiency, and creative possibilities. Its impact extends beyond the production floor, influencing design, education, and the very way we think about wood as a material. As technology continues to evolve, the potential of CNC woodworking seems limitless, promising even more exciting developments in the years to come.

In embracing CNC technology, woodworkers are not just keeping pace with the times; they are forging a new future for their craft. The Wood CNC router is more than a tool; it is a catalyst for innovation, a bridge to new opportunities, and a testament to the enduring appeal of woodworking in the digital age.