Table of Contents

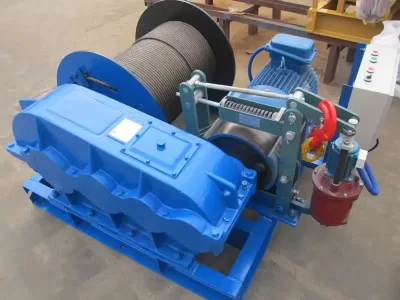

ToggleAn electric winch is a powerful tool, invaluable for off-road enthusiasts, maritime applications, and heavy-duty lifting in construction or industrial settings. Whether you’re recovering a vehicle stuck in the mud, pulling heavy loads on a job site, or securing cargo on a boat, your winch is a critical piece of equipment that can make the difference between success and failure.

However, like all mechanical devices, your electric winch requires proper maintenance to function at its best and to last for years to come. Regular maintenance not only ensures your winch operates smoothly but also prevents costly repairs and extends its lifespan. In this blog, we’ll share some essential maintenance tips to help you keep your electric winch in peak condition, so it’s ready for action whenever you need it.

Why Is Winch Maintenance Important?

Regular maintenance for your electric winch is essential for several reasons:

-

Ensures Safety: A malfunctioning winch can lead to dangerous situations, especially when you’re towing or lifting heavy loads. Keeping your winch in good working order reduces the risk of accidents.

-

Maximizes Performance: A well-maintained winch operates more efficiently, providing better pulling power, smoother operation, and faster recovery times.

-

Prevents Wear and Tear: The more you use your winch, the more prone it is to wear, corrosion, and damage. Maintenance helps to minimize this, keeping parts like the cable, motor, and gears functioning properly.

-

Extends Lifespan: With regular care, you can maximize the lifespan of your winch and get years of reliable service, avoiding the need for premature replacements.

1. Clean Your Winch Regularly

Cleaning your electric winch is one of the simplest and most effective ways to maintain its performance. Dirt, mud, sand, and other debris can cause parts to wear out prematurely, affect the motor’s efficiency, and potentially damage the cable.

How to Clean Your Winch:

-

After Each Use: If you’ve been off-roading or using your winch in harsh conditions, take the time to clean it afterward. Use a soft brush or cloth to remove dirt and debris from the winch’s exterior.

-

Rinse with Fresh Water: If your winch has been exposed to saltwater (in maritime or coastal environments), rinse it off with fresh water to prevent corrosion. Use a hose with moderate water pressure, but avoid blasting high-pressure water directly into sensitive components like the motor or control box.

-

Lubricate Moving Parts: After cleaning, apply lubricant to the moving parts of the winch, including the drum and gears. This will help keep the components running smoothly.

2. Inspect the Winch Cable or Rope

The winch cable or rope is one of the most critical components, as it bears the entire load when pulling or lifting. Regular inspections are necessary to ensure that the cable or rope remains in good condition, especially after heavy use.

How to Inspect the Cable/Rope:

-

Look for Fraying or Damage: Check the cable for any signs of fraying, cuts, or abrasions. A damaged cable can snap under tension, leading to dangerous situations. If you’re using a synthetic rope, inspect it for signs of wear or UV damage.

-

Check for Kinks: Kinks in the rope or cable can weaken it, causing it to break more easily. Gently straighten any kinks and ensure the rope is coiled evenly on the drum.

-

Clean the Rope: Synthetic ropes can accumulate dirt and debris. Wash them periodically with mild soap and water, and allow them to air dry completely. Avoid using harsh chemicals that could weaken the rope fibers.

For Steel Cables:

-

Check for Rust: Steel cables are prone to rust, especially if exposed to moisture. Look for any signs of rusting, particularly after use in wet or saltwater conditions.

-

Apply Lubricant: After cleaning and inspecting the cable, apply a winch cable lubricant to prevent rust and corrosion.

For Synthetic Ropes:

-

Avoid UV Exposure: Synthetic ropes are sensitive to ultraviolet (UV) rays, which can degrade the fibers over time. Whenever possible, cover the rope when not in use or store the winch in a shaded area.

3. Check the Motor and Electrical Connections

The motor is the heart of your electric winch, so keeping it in good working order is essential. Regular checks of the motor and its electrical connections will help avoid overheating, malfunctions, or a sudden loss of power.

How to Maintain the Motor and Electrical Connections:

-

Inspect for Corrosion: Corrosion is a major issue in environments with high humidity or saltwater. Check the motor’s housing and electrical connections for signs of corrosion or rust, and clean them gently with a wire brush or cloth.

-

Tighten Loose Connections: Over time, the vibrations from winching can cause electrical connections to loosen. Check the wiring and terminals, and tighten any loose connections. Loose wires can cause performance issues or even prevent the winch from operating.

-

Test the Motor: Periodically, you should test the winch motor by operating it without a load. This will help you identify any performance issues, such as a motor that is running weakly or inconsistently.

4. Lubricate the Winch Components

Just like any other mechanical tool, the components of an electric winch need lubrication to reduce friction and ensure smooth operation. Lubricating the gears, drum, and other moving parts will help them function more efficiently and prevent wear.

How to Lubricate Your Winch:

-

Use the Right Lubricant: Choose a lubricant that’s designed for winches or heavy-duty equipment. Avoid using automotive grease or oil, as they may not provide the right level of protection for the winch.

-

Lubricate the Drum and Gears: Apply a light coat of lubricant to the winch drum and gear system. This helps reduce friction and keeps the winch running smoothly.

-

Avoid Over-Lubricating: Too much lubrication can attract dirt and debris, which can lead to build-up and reduced performance. Apply just enough to keep parts well-coated.

5. Test the Winch Periodically

Regularly testing your winch, even when you’re not using it for a recovery or towing task, is an excellent way to ensure that all parts are functioning correctly. Testing allows you to catch small issues before they become major problems.

How to Test Your Winch:

-

Without a Load: Perform a dry run by operating the winch without a load to test the motor, cable, and controls. This can help you identify any mechanical or electrical issues that need attention.

-

With a Load: If possible, test your winch with a light load to ensure it can pull effectively and smoothly. This will simulate real-world conditions and help you spot any issues with the winching process.

6. Store the Winch Properly

Proper storage of your winch is essential, especially if you’re not using it frequently. Storing your winch in a clean, dry location will help protect it from dust, dirt, and moisture, which can accelerate wear.

Storage Tips:

-

Cover the Winch: If your winch is mounted on a vehicle, cover it with a winch cover when not in use. This will keep it free of dirt and debris and protect it from the elements.

-

Store the Rope/Cable Carefully: Always make sure the rope or cable is properly spooled onto the drum. Avoid leaving any slack or tangles, as this can lead to issues when you need to use the winch.

Conclusion

Maintaining your electric winch is a key part of ensuring that it operates safely and efficiently for years to come. By cleaning the winch regularly, inspecting the cable or rope, checking electrical connections, lubricating components, and testing the system periodically, you can prevent costly repairs and maximize the performance of your winch. Taking care of your winch ensures that it’s always ready to help when you need it most, whether you’re recovering a vehicle on a muddy trail or pulling heavy loads at a worksite. With these maintenance tips, you’ll enjoy many more off-road adventures with peace of mind!